Mooring Dextron

The Dextron® mooring ropes made with Dyneema® offers a light weight mooring rope system which is easy to handle and has increased service lifetime compared to steel wire and generic HMPE fiber ropes. Repair or re-splicing can easily be carried out on board the vessel. With its qualities it has safety benefits with less crew injuries and less maintenance on rope and ship.

Dextron®12 Plus is a torque-free, 12-strand braided rope with maximum strength-to-weight ratio and size-for-size has the same strength as steel. Dextron®12 Plus is made with Dyneema® SK78 and is an excellent wire rope replacement with extremely low stretch, superior flex fatigue and wear resistance.

Dextron®12 Plus is Type-Approved by DNV. Download certificate

|

Applications

|

Special Properties

|

Characteristics:

| Material | Dyneema®SK78 |

| Colour of rope | Yellow |

| Elastic elongation | 0,44% at 10% of breaking load 0,62% at 20% of breaking load 0,79% at 30% of breaking load |

| Water absorption | None |

| Abrasion resistance | Very good |

| Fatigue resistance | Excellent |

| UV exposure | Very good |

| Chemical resistance | Excellent |

| Melting range | 144-152 ºC |

| Max work temp. | 65ºC |

| Specific density | 0,98 (floating) |

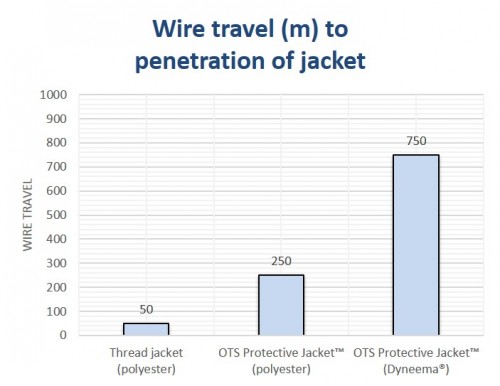

The patented chafe gear - OTS Protective jacket™ - offers excellent protection against external abrasion and increases rope lifetime with up to five times. The "no-rupture" construction combined with the worlds most abrasion resistant synthetic fibers, makes this the best cut -and abrasion resistant cover for your ropes. The jacket is mechanically braided onto the rope for a firm and solid finish.

OTS Protective jacket™ is braided in the following combinations:

- Soft eyes

- Soft eyes and required length (for instance over the splices)

- Exposed area on the rope

- Entire rope length

|

OTS Protective Jacket™

|

Advantages

|