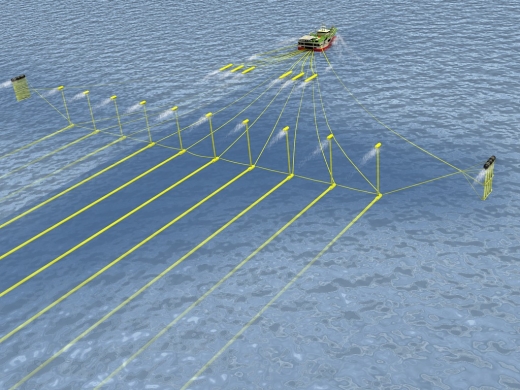

Main tow rope

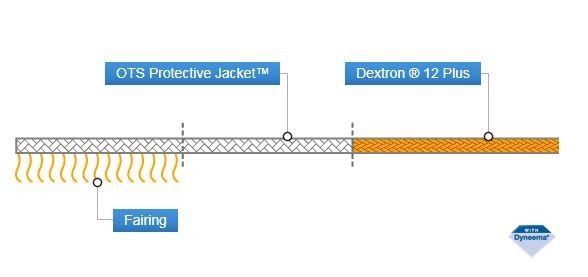

The Dextron® main tow rope is made with Dyneema® and is delivered as a plain rope or in combination with OTS Protective jacket™ and fairing. The advantage of the OTS Protective jacket™ is excellent abrasion resistance and a very durable protection against cutting.

The high strength-to-weight ration, on the relatively small diameter ropes, enable the vessel to tow large arrangements with minimal drag. Fairing solutions reduce strumming and acustical noise, and contributes to significant fuel savings.

OTS constantly work on developing new solutions to improve the beneficial characteristics in the main tow rope.

Below you can find more information about our Dextron® ropes and components used in our main tow products.

Dextron®12 Plus is a torque-free, 12-strand braided rope with maximum strength-to-weight ratio and size-for-size has the same strength as steel. Dextron®12 Plus is made with Dyneema® SK78 and is an excellent wire rope replacement with extremely low stretch, superior flex fatigue and wear resistance.

Dextron®12 Plus is Type-Approved by DNV. Download certificate

|

Applications

|

Special Properties

|

Characteristics:

| Material | Dyneema®SK78 |

| Colour of rope | Yellow |

| Elastic elongation | 0,44% at 10% of breaking load 0,62% at 20% of breaking load 0,79% at 30% of breaking load |

| Water absorption | None |

| Abrasion resistance | Very good |

| Fatigue resistance | Excellent |

| UV exposure | Very good |

| Chemical resistance | Excellent |

| Melting range | 144-152 ºC |

| Max work temp. | 65ºC |

| Specific density | 0,98 (floating) |

Based on the construction of the Dextron® 12 Plus rope. Made with Dyneema® XBO fiber for improved cyclic bending properties. 12-strand torque-free rope construction with with round and firm shape. Maximum strength-to-weight ratio and size-for-size has the same strength as steel. Extended service lifetime in applications with multiple bending.

|

Applications

|

Special Properties

|

Characteristics:

| Material | Dyneema®SK78 XBO |

| Colour of rope | Yellow with black tracer |

| Elastic elongation | 0,44% at 10% of breaking load 0,62% at 20% of breaking load 0,79% at 30% of breaking load |

| Water absorption | None |

| Abrasion resistance | Very good |

| Fatigue resistance | Excellent |

| UV exposure | Very good |

| Chemical resistance | Excellent |

| Melting range | 144-152 ºC |

| Max work temp. | 65ºC |

| Specific density | 0,98 (floating) |

Dyneema® XBO Technology is a special coating that is only available in combination with Dyneema® fiber. Contact us for strength and dimensions.

Break load in accordance with DIN EN ISO 2307

Manufactured by Offshore & Trawl Supply AS – Certified according to ISO 9001:2015

Maximum strength without compromise. The Dextron® 12 Super is a rope made with Dyneema® SK99 - the ultra-strong fiber. Dextron® 12 Super is the optimal choice for operations with very high demand on modulus and breaking strength.

Characteristics

| Material | Dyneema® SK99 |

| Colour of rope | Yellow with gold tracer |

| Elastic elongation | 0,44 at 10% 0,62 at 20% 0,79 at 30% of breaking load |

| Water absorption | None |

| Abrasion resistance | Very good |

| Fatigue resistance | Excellent |

| UV exposure | Very good |

| Chemical resistance | Excellent |

| Melting range | 144-152 ºC |

| Max work temp. | 65ºC |

| Specific density | 0,98 (floating) |

Dyneema® SK99 is the latest innovation for highest level of performance. Dyneema®SK99 has the highest tenacity (42.5 cN/dtex) and modulus (1590cN/dtex) of any lightweight polymer fiber. Result: ropes that respond with micro precision resulting in maximum speed. Contact us for strength and dimensions.

Break load in accordance with DIN EN ISO 2307

Manufactured by Offshore & Trawl Supply AS – Certified according to ISO 9001:2015

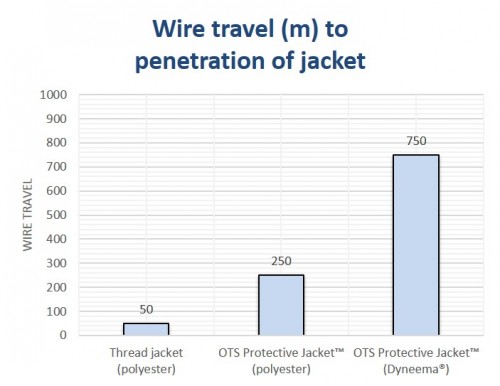

The patented chafe gear - OTS Protective jacket™ - offers excellent protection against external abrasion and increases rope lifetime with up to five times. The "no-rupture" construction combined with the worlds most abrasion resistant synthetic fibers, makes this the best cut -and abrasion resistant cover for your ropes. The jacket is mechanically braided onto the rope for a firm and solid finish.

OTS Protective jacket™ is braided in the following combinations:

- Soft eyes

- Soft eyes and required length (for instance over the splices)

- Exposed area on the rope

- Entire rope length

|

OTS Protective Jacket™

|

Advantages

|

Fairing reduce the turbulence that occurs when a object is being towed through the water. The fairing OTS supply comes in two types; hairy fairing and solid fairing.

The hairy fairing is either tied to the rope by hand or automatically braided into the protective jacket™. The hairy fairing can be made with fibers like PE-yarn, Danline, Dyneema® or Polyester. Recent years testing in laboratory and fieldtests has given further information about the effect of reducing drag by means of fairing. OTS is continously developing new fairing types based on information from these type of tests. Contact us to learn more about our recent developments.

The solid fairing is a wing shaped component mostly made of PE or similar material. The fairing is - at its name states - a solid construction that is being threaded onto the rope and secured to the rope every 5 or 10 meters. This fairing type is especially effective on drag reduction where the rope is being towed in a transverse direction.